IP-69K Stainless Steel AC Worm Gearmotors

Most stainless steel gearmotors are rated IP-66 or higher, and are typically hermetically sealed to prevent water or particle ingress from frequent high-pressure washdowns. The IP-69K rating is defined via two industry standards: IEC 60529,

The second standard is ISO 20653: for Road Vehicles – Degrees of Protection (IP Code) – Protection of Electrical Equipment Against Foreign Objects, Water and Access. IP-69K rated gearmotors are ideal for production conditions in the food and beverage industry, pharmaceutical industry, and in permanently wet environments.

EXPLORE OUR IP-69K AC GEARMOTORS

IP-69K Specifications

- Cover electrical equipment enclosures mounted to road vehicles

- Requires that the water jet pressure be measured during the test.

- The distance from the water nozzle to the motor is a minimum of 100mm min

- The maximum water jet temperature for both tests is 85±5°C (176°F).

Solid Protection

| 0 | Non protected. |

| 1 | Protected against a solid object greater than 500 mm, such as a hand. |

| 2 | Protected against a solid object greater than 12 mm, such as a finger. |

| 3 | Protected against a solid object greater than 2.5 mm, such as a screwdriver. |

| 4 | Protected against a solid object greater than 1 mm, such as most screws and wires. |

| 5 | Dust protected. Prevents ingress of dust sufficient to cause harm. |

| 6 | Dust tight. No ingress of dust. |

Water Protection

| 0 | Non protected. |

| 1 | Protected against vertical dripping water. . |

| 2 | Protected against vertical dripping water when tilted up 15°. |

| 3 | Protected against spraying water at an angle of 60°. |

| 4 | Protected against splashes of water at any angle. |

| 5 | Protected against low pressure water jets from any direction. |

| 6 | Protected against high pressure water jets from any direction. |

| 7 | Protected against the effects of immersion in water between 15cm and 1m for 30 minutes. |

| 8 | Protected against the effects of immersion in water under pressure for long periods. |

| 9 | Protected from close-range, high-pressure, high-temperature water jets. |

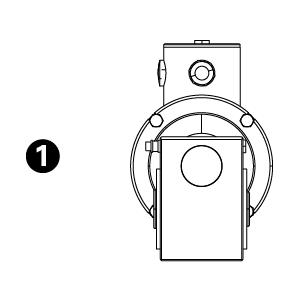

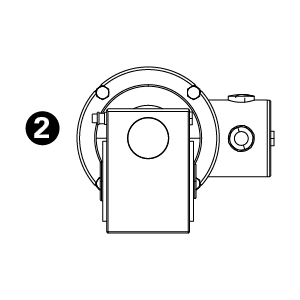

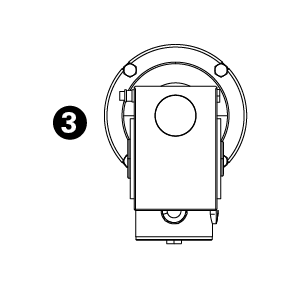

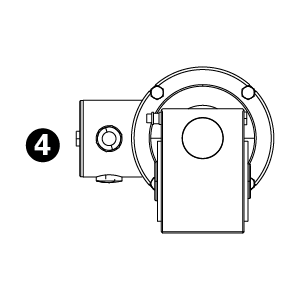

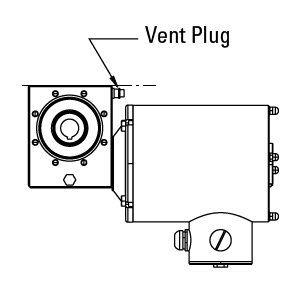

Alternative Terminal Box Positions

Many IP-69K gearmotors allow the user to reposition the terminal box by rotating the motor in 90 degree increments as shown. The standard terminal box orientation for Bodine stainless steel gearmotors is the 12 o’clock position.

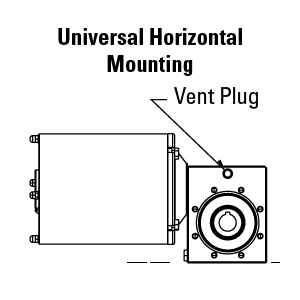

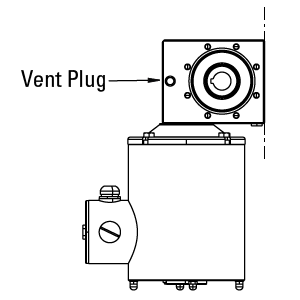

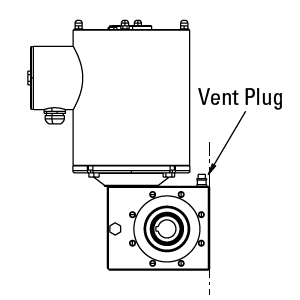

Mounting an IP-69K Gearmotor

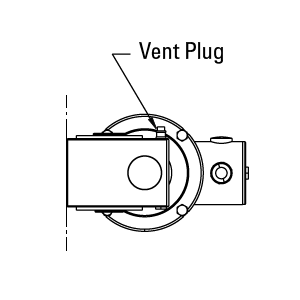

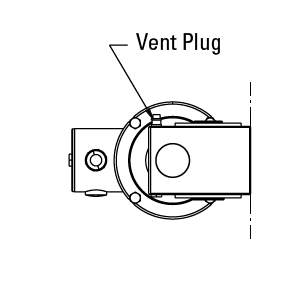

- Universal horizontal mounting for IP-69K gearmotors is shown in the first diagram.

- Other horizontal positions: the vent plug must always be either above or in line with the output shaft centerline. Exchange the vent plug with the one of the other threaded plugs on the gearbox as shown.

- Vertical mounting positions: To mount the gearmotor so that the shaft is oriented vertically, make sure that the vent plug is at the top of the gearbox face as shown.

Wiring an IP-69K Gearmotor

Use a heavy-duty power cable rated SJOW or SJT with diameter of .275 to .492 inches.

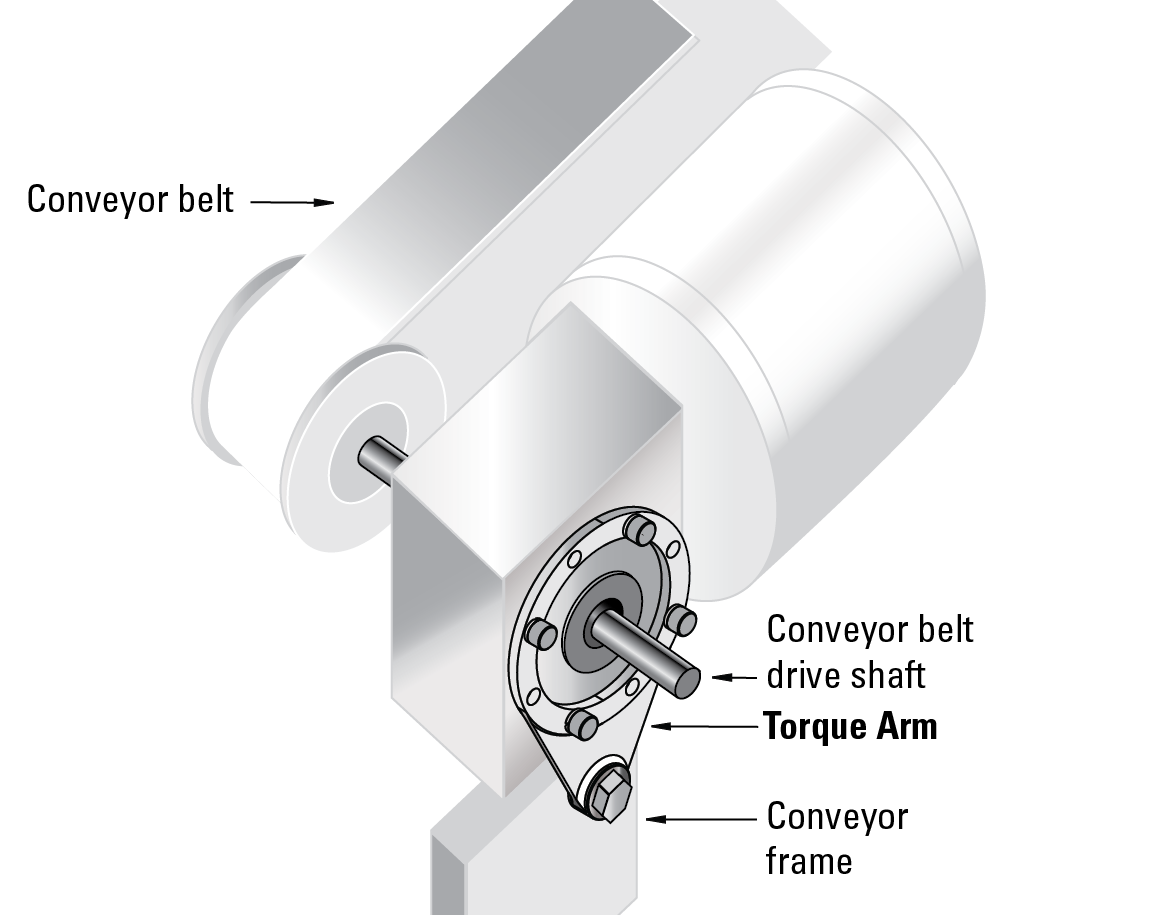

Mounting an IP-69K Gearmotor with a Torque Arm

A torque arm allows the gearmotor to self-align with the conveyor belt drive shaft.

The torque arm is mounted to the face-mount holes as shown, and allows the gearmotor to float on the shaft. The key benefit of this mounting method is that it eliminates the risk of gearmotor shaft misalignment. This mounting configuration prevents bearing failures on the conveyor or gearhead and it reduces the risk of shaft fatigue fractures.

Stainless Steel Torque Arms Kit