Bodine Gearmotor 1-2-3 Selection Guide

This selection guide was designed to help you specify the best motor, gearmotor and control solution for your application. By considering three key design criteria, you can quickly select a drive system that should meet your application needs: (1) Determine the required speed and torque. (2) Select the appropriate motor type. (3) Select gear reducer, if needed. Bodine literature no. 07481011B.

Download PDF

The Engineer’s Guide to Driving 3-Phase AC Induction Motors with Inverters

The Engineer’s Guide to Selecting the Best Gearmotor

The Engineer’s Guide to AC Gearmotor Nameplate Ratings

In this whitepaper, we will take a deep dive into the nameplate ratings of single-phase AC gearmotors, and how to interpret their specifications for optimal performance.

Download PDF

DC - 07470077.A Filtering Tips For Bodine type WPM and UPM Controls in Industrial Machines

This PDF provides guidelines for installing Bodine type WPM and UPM controls in equipment or applications that are sensitive to Electromagnetic Interference (EMI). Bodine literature no. 07470077A. Updated 06/2022.

Download PDF

IP-69K Stainless Steel AC Worm Gearmotors

Most stainless steel gearmotors are rated IP-66 or higher, and are typically hermetically sealed to prevent water or particle ingress. In this application note, we review how IP-69K is defined and what it means for your application: read about IEC 60529, Degrees of Protection Provided by Enclosures, which defines IP-69 as, 6 = dust tight and 9 = high pressure water jet resistant, and the “K” from ISO 20653. We also provide installation tips for these IP-69K gearmotors. Bodine literature no. 07400078A.

Download PDF

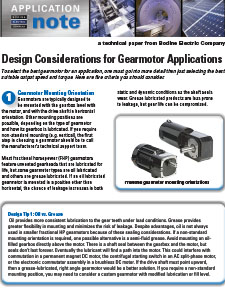

Features and Benefits of Hypoid Gearmotors

Right-angle gearmotors with hypoid gearsets have several advantages when compared with standard worm-and-pinon right-angle gearmotors. Hypoid gearmotors are more efficient, produce less heat, provide higher torque, and are usually smaller than equivalent gearmotors with worm-and-pinion reducers.

Download PDF

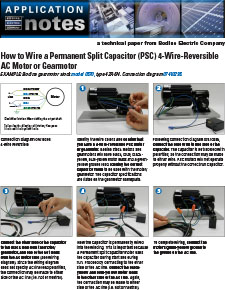

Wiring a 34B/SR-WX Gearmotor in Non-Hazardous Locations

How-To Instructions

This application note explains the steps to properly wire our standard 34B/SR-WX, 12/24VDC gearmotors for remote operation in a non-hazardous location. For remote operation of these products in a Class I, Division 2, Groups A, B, C, or D hazardous environment, please review your local safety rules and regulations.

Download PDF

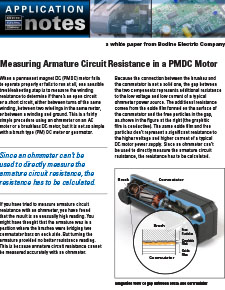

Deviations from Recommended AC Motor Capacitor Rating and Their Consequences

You can get higher starting torque from an AC induction motor by replacing factory specified capacitors with larger ones. But pushing the motor too far beyond design specs is risky. Learn how capacitance affects motor performance. Bodine literature no. 07400079A.

Download PDF

Typical Operating Conditions for AC Gearmotors and Motors

Engineering Tips

This tech note explains how operating an AC induction gearmotor or motor beyond the ratings shown on the product nameplate can affect its performance. Bodine literature no. 074700765A

Download PDF