Author’s note: I contributed a column for the June 2025 issue of Tech Brief’s Motion Design supplement about putting encoders on motors. Because it was supposed to be a technical article, and not a sales pitch for Bodine Electric products, I had to keep the content “generic”. For our Bodine Blog, I created an extended version that includes additional photos, links to specific Bodine products, and features described in the article.

Encoders on Motors Fix Motion Disorders

Many machines benefit from having an encoder on a gearmotor. The gearmotor may need an encoder to provide feedback to a servo controller in order to precisely control its position, such as in a warehouse robot. It may need to communicate its progress to a controller while executing a time-sensitive process, like driving a conveyor that transports pizzas through an oven without undercooking or burning the pizza. Or the gearmotor may need an encoder simply to verify to the Industrial Internet of Things that it is rotating when expected, as in a chemical injection pump operating in a remote oil field. The first step for any of these applications is selecting a gearmotor that supports encoder installation. All the examples above involve small fractional horsepower gearmotors. Typically, encoders mount on an extension of the high-speed motor shaft rather than the gearbox’s low-speed output shaft. There are three common options for encoder-compatible gearmotors: accessory shaft, shaft extender, and hall sensor output.

Accessory Shaft

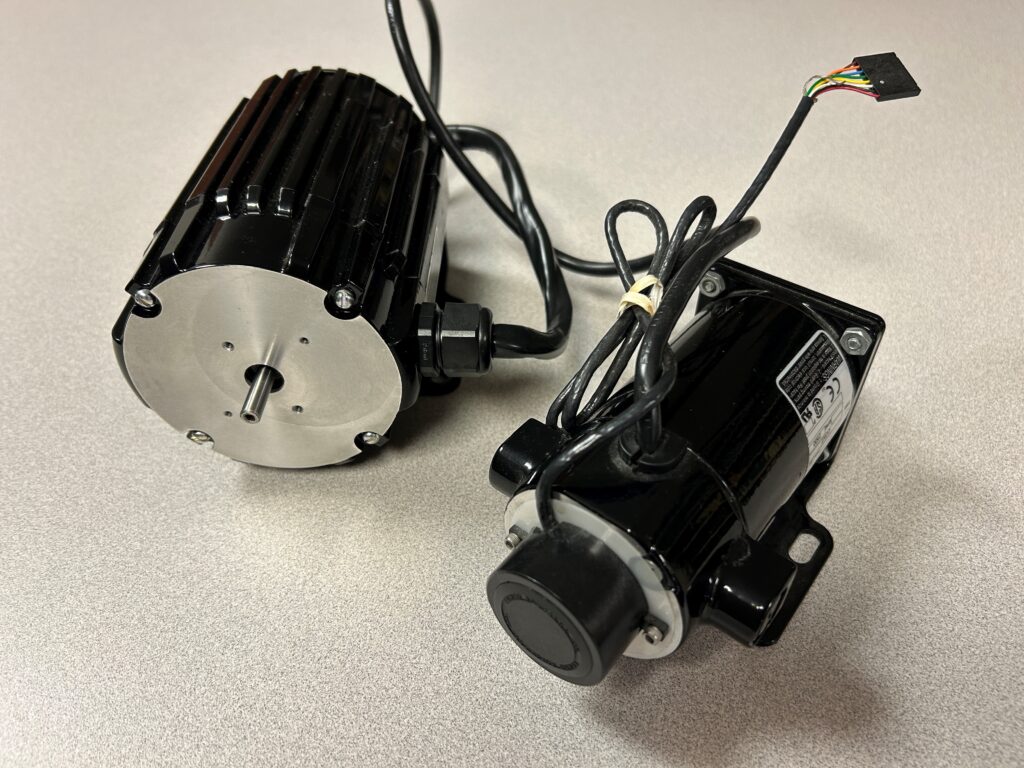

Some motors and gearmotors include an external extension of the motor shaft, along with mounting provisions on the motor endshield for accessories like encoders. These are ideal for modular, hollow-bore encoders that slide over the motor shaft. Common fractional horsepower motor shaft diameters include 1/4″ and 3/8″. Two examples of Bodine motors with a shaft extension for an encoder are shown at the right. Bodine model 3409, on the left, has a shaft extension and a machined surface, with mounting holes, to mount an encoder. Bodine model 0047, on the right, also has a shaft extension and machined mounting surface, and is shown with an encoder already attached to it.

Shaft Extender

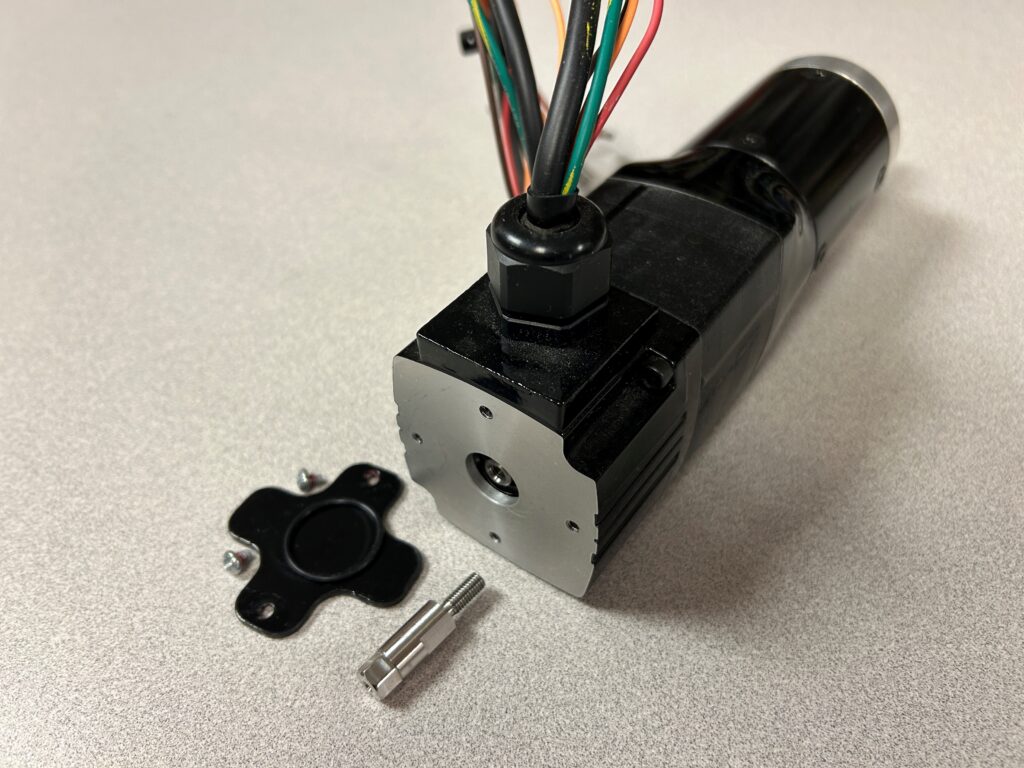

Some motors and gearmotors have a hole in the motor endshield to expose the end of the motor shaft, which doesn’t extend outside the motor. A threaded hole in the end of the motor shaft allows a shaft extender to be added to mount an encoder. This flexible design keeps the high-speed shaft covered in applications that don’t require an encoder. An example of this is shown at the right. Bodine model 7030 is shown with the cover removed to expose the end of the motor shaft. Bodine shaft extender model 0964 is shown about to be installed.

Hall Sensor Output

Most brushless DC motors and gearmotors have built-in hall sensors used for commutation. The outputs from those hall sensors can also provide speed feedback. This is suitable for lower-resolution needs, like the pizza oven or remote pump examples. The signal is often accessed via the speed control, eliminating the need for a separate encoder or mounting solution. An example of this is Bodine model 3288, shown at right. This brushless DC gearmotor has a speed control attached to the side (shown with the cover removed) and a 12 pulse/revolution tach output is available from a connector on the circuit board.

Once you have identified a gearmotor that can accept an encoder, you can move on to specifying the encoder type, construction, output signal, and resolution. Some encoder manufacturers that Bodine Electric works with include Quantum Devices, Encoder Products Company, Dynapar, Same Sky (formerly CUI Devices), and Timken Encoders. Since there are many encoder manufacturers and products to choose from, finding the right encoder is generally not as challenging as finding the right gearmotor to mount it to.