Large distribution warehouses operated by wholesalers, retailers, or large manufacturers have turned to Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) to keep up with ever-increasing demand for faster and more economical deliveries. A major original equipment manufacturer (OEM) for AGVs contacted Bodine Electric Company to help develop two new custom gearmotors for their latest AGV. Bodine has since built, tested and shipped over 50,000 gearmotors to this customer.

Large distribution warehouses operated by wholesalers, retailers, or large manufacturers have turned to Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) to keep up with ever-increasing demand for faster and more economical deliveries. A major original equipment manufacturer (OEM) for AGVs contacted Bodine Electric Company to help develop two new custom gearmotors for their latest AGV. Bodine has since built, tested and shipped over 50,000 gearmotors to this customer.

The Challenge

The OEM’s specifications required two gearmotors, one of them had to lift up to 1,000 lbs (with substantial peak loads). The AGV’s chassis had already been finalized, and left only limited space for the new gearmotors. The gearmotors were required to operate almost continuously for five years, under worst-case environmental conditions, and would be subjected to extreme vibration and shock.

The Result

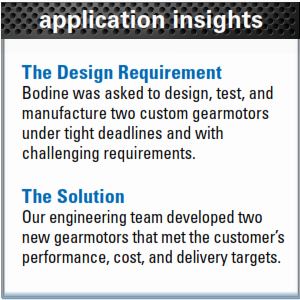

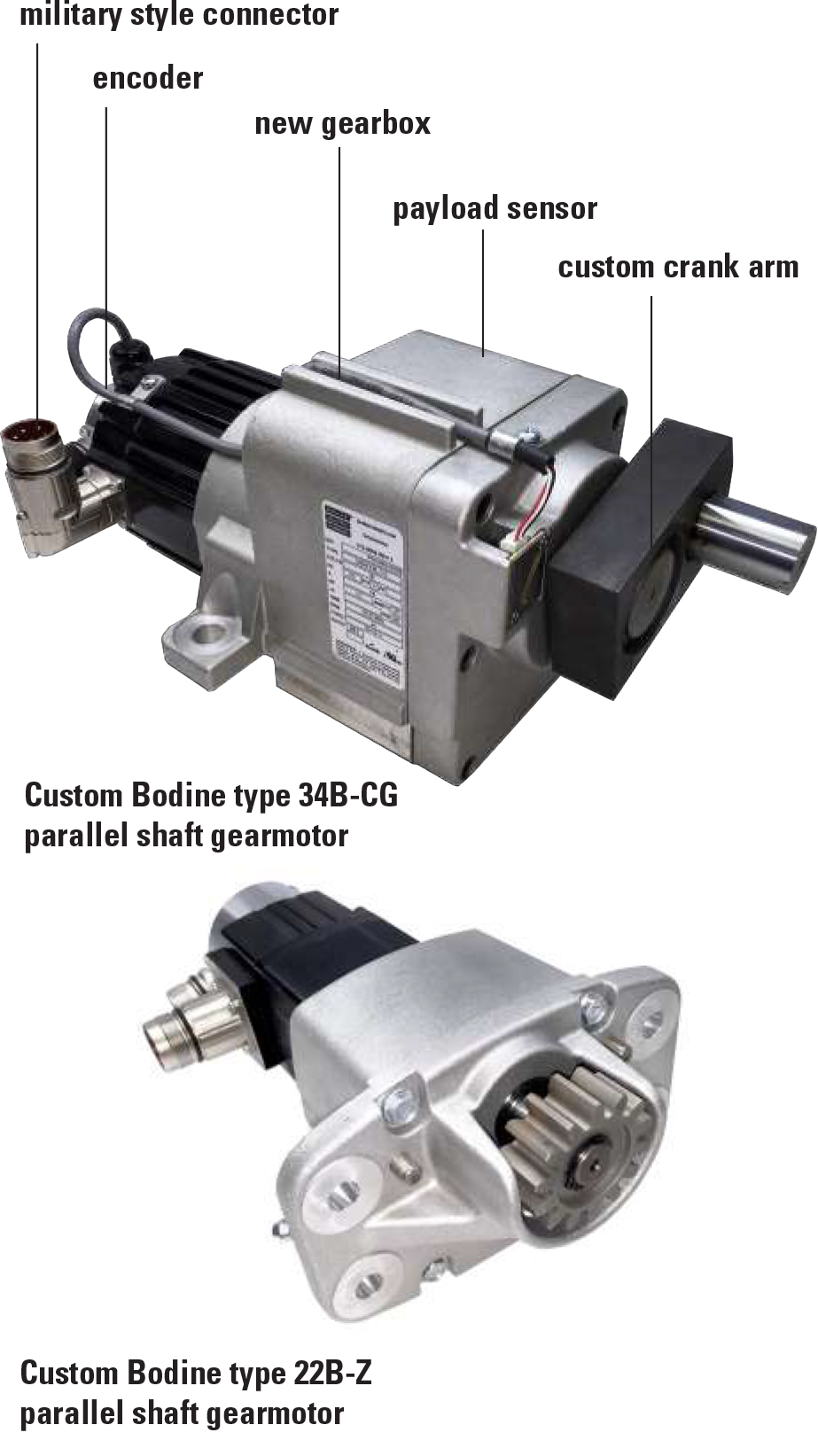

Almost every part of these new gearmotors was engineered to match the customer’s extensive list of requirements.

- Low-voltage brushless DC motors paired with all-new, highly efficient gearboxes prolong the AGV battery life and minimize downtime

- Gearbox designed to simplify the assembly process of the AGV

- Custom output shaft assembly designed for extremely heavy loads

- Feedback device tracked the position of the drive shaft

- 1024 PPR encoder provided servo feedback to control the gearmotors

- “Military Style” plug and screw connections

- Temperature sensors monitor gearmotor performance and to prevent overloads

- Manual over-ride in the event of a power failure

With Bodine’s help, these sophisticated robotic vehicles have been performing flawlessly all over the world. Bodine not only developed two entirely new gearmotors for the application, they also helped navigate the difficult third-party approval process. Bodine engineers extensive experience in motion control made them an ideal partner in the development of this new product, which in turn is making warehouse jobs easier, more productive, and cost-efficient.

With Bodine’s help, these sophisticated robotic vehicles have been performing flawlessly all over the world. Bodine not only developed two entirely new gearmotors for the application, they also helped navigate the difficult third-party approval process. Bodine engineers extensive experience in motion control made them an ideal partner in the development of this new product, which in turn is making warehouse jobs easier, more productive, and cost-efficient.

Bodine Electric engineers bring over 115 years of application engineering and problem solving experience to a wide range of applications in industries as diverse as medical, packaging, industrial automation, and solar powered outdoors equipment. We look forward to working with you on your next FHP gearmotor design challenge.

To download this article as a PDF, click here

Copyright Bodine Electric Company © 10/2021.

All rights reserved.