Buyers should first decide what kind of operating life is needed. If durability is not an issue, or if the duty is so intermittent that even a short-life (“throw-away”) motor will translate into years of operation, then you’ll want to go with the best price.

But if product quality and reputation depends on reliability and high performance, or the gearmotor will be maintained rather than replaced, then other factors should be considered. A less expensive gearmotor that needs to be replaced several times can cost more in the long-run. And there may also be a more direct cost if the gearmotor fails before the product warranty has expired.

1) Total Operating Hours. To determine the correct gearmotor life, you need to calculate the total hours of operation.

Intermittent Duty. A gearmotor application that drives an actuator back and forth for 30 seconds every 10 minutes, and will run for one 8-hour shift five days a week, needs a gearmotor that will operate trouble-free for 416 hours (over 2 years).

(1 min./cycle) x (6 cycles/hr.) x (1 hr./60 min.) x (8 hrs./day) x (5 days/week) x (52 weeks/year) x 2 years = 416 hours/2 years

Continuous Duty. A gearmotor, that runs a conveyor continuously for three 8-hour shifts, seven days a week, needs to be trouble-free for 8,736 hours/ year (17,472 hrs/2 yrs). A huge difference in operating requirements.

(24 hrs./day) x (7 days/week) x (52 weeks/year) x 2 years = 17,472 hours/2 years

2) Design Life. Finding a gearmotor with the life expectancy that your application requires is challenging. Most gearmotor manufacturers don’t publish design life ratings. Some, because they haven’t tested for it, others, because gear reducer life is dependent on a variety of variables which can include, but are not limited to, start frequency, shock loads, operating speed, actual load and operating temperature. These companies will have you talk to an application engineer about design life estimates.

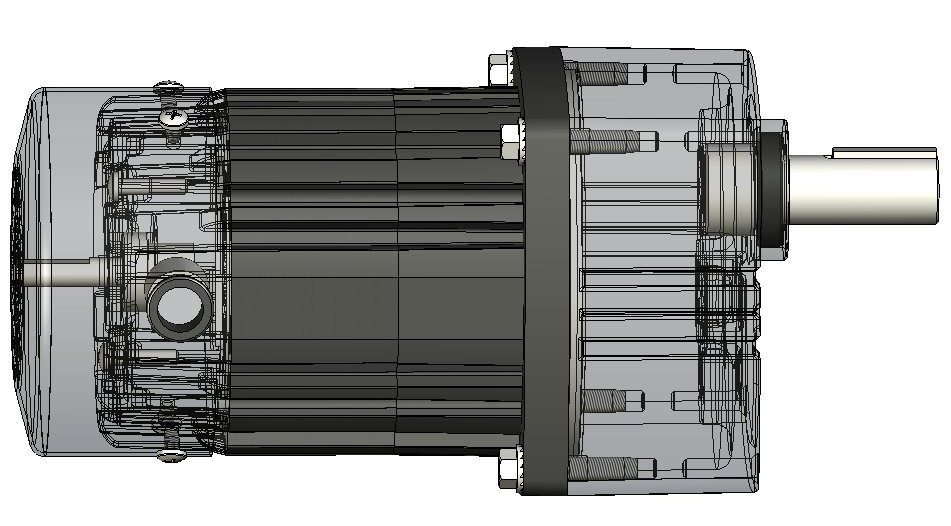

3) Output Torque. It’s an excellent example of how one specification can affect design life. One manufacturer may rate their gearmotor’s output torque at 100 lb-in., however, it may last only 1,000 hours. A gearmotor rated at 40 lb-in. from a different supplier may last 10,000 hours or longer. How the specs are measured makes all the difference. Another problem to watch out for is that while some manufacturers make integral gearmotors with a single nameplate, others mate a stand-alone motor to a separable gear reducer. In this case, the motor and the gear reducer may each have their own nameplates. The output torque rating of the gear reducer is what it is capable of, not necessarily what it will actually produce with a given motor. This matching may overload the gear reducer, greatly limiting its life. See calculation examples below.

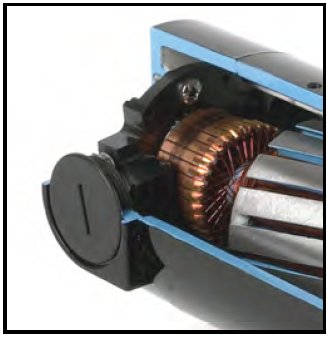

4) Brush-type DC Motors. Brushes are only a concern with PMDC, universal or series wound DC motors. By their design, motor brushes are intended to be replaced. So for applications that require long life and therefore will need regular maintenance and inspection, you’ll want a motor designed with external access for easy replacement. Gearmotor manufacturers are reluctant to quote brush life specifications because, even more so than gear reducers, brush life is dependent on more variables. A good example is motor speed; the higher the speed, the faster the brushes wear out. So you need to watch for manufacturers that may minimize the gearmotor size by using a very high speed motor to take advantage of the torque-multiplying effect of a high gear ratio. This combination has a smaller package size than a lower speed motor with a lower gear ratio, but it will also have a shorter brush life, a higher operating noise level, and brushes that need more frequent inspections and replacement. Another variable affecting brush life is the form factor (F.F.) of the DC current, if an SCR type speed control is used. A gearmotor used with an unfiltered full wave rectified control (1.6 form factor) will have about half the brush life than a gearmotor used with a filtered control (1.0 form factor).

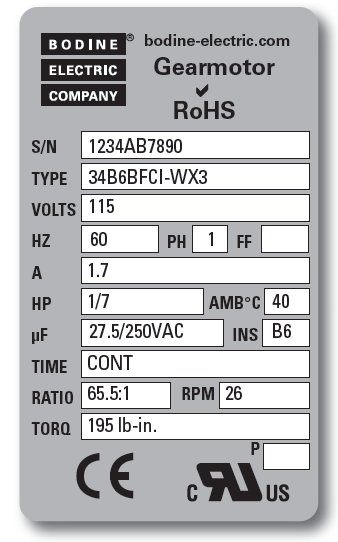

5) Ambient Temperature. Not all gearmotor manufacturers include an ambient temperature rating. Whether they do or don’t, the gearmotor is restricted to a certain ambient temperature anyway. This is because the horsepower rating is based on keeping the sum of the increase in winding temperature plus the ambient temperature within the insulation class temperature limit. If there is no ambient temperature rating given on the nameplate, then ask the manufacturer what it is. To illustrate the importance of knowing the ambient temperature rating, consider two gearmotors, both rated at 1/4 HP. One is rated at 25°C and the other is rated at 40°C. If the actual load really is 1/4 HP, and the actual ambient temperature is 25°C, then either gearmotor can be used. However, if the actual ambient temperature is 40°C, then the gearmotor rated at 25°C would run hotter than recommended for its insulation class, and its life would be reduced. As a general rule, both lubricant and insulation life is cut in half for every 10°C increase in operating temperature.

Calculations: Output Torque of a Motor and Gearhead Combination

Output torque = input motor torque x gear ratio x gear efficiency (assume 80% gear efficiency; seal friction ignored for this example)

Example 1: Reducer: 100 lb-in., 20:1 ratio; Motor: 10 oz-in. @ 1,700 rpm; Result: 10 lb-in. output torque.

The mating of a 100 lb-in., 20:1 gear reducer to a 10 oz-in. at 1700 rpm (1/60 HP) motor produces only a 10 lb-in. output torque rating. This can mean overheating, slower output speed, or a gearmotor that can’t even start the load. (10 oz-in. x 20 x .80 x [1 Ib-in./16 oz-in.]) = 10 Ib-in.) Conclusion: this reducer is rated at 100 lb-in., but the motor is not strong enough

Example 2: Reducer: 100 lb-in., 20:1 ratio; Motor: 300 oz-in. @ 1,700 rpm; Result: 300 lb-in. theoretical output torque.

On the other hand, if the same gear reducer is mated to a motor rated 300 oz-in. at 1,700 rpm (1/2 HP), then the output torque would be 300 lb-in., which is three times the rating of the gear reducer. This overloading of the gear reducer will greatly decrease its actual life. Conclusion: the gear reducer is undersized for the selected motor.

To download the PDF version, click here.

Copyright Bodine Electric Company © 05/2012. All rights reserved.