Worm gearing is a proven and economical solution for applications that require high speed reductions in limited space, and with very smooth and quiet operation. Worm gears have inherent self-locking ability depending on design and ratio. Lubrication is very important for the life of the worm gear set and efficiency can be improved by using enveloping worm sets.

Description

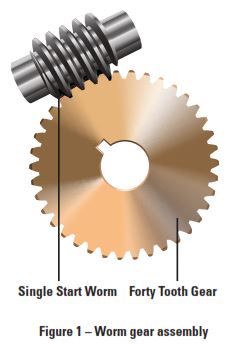

A worm gear assembly resembles a single threaded screw that turns a modified spur gear with slightly angled and curved teeth. Worm gears can be fitted with either a right-, left-hand, or hollow output (drive) shaft. This right angle gearing type is used when a large speed reduction or a large torque increase is required in a limited amount of space. Figure 1 shows a single thread (or single start) worm and a forty tooth worm gear resulting in a 40:1 ratio. The ratio is equal to the number of gear teeth divided by the number of starts/threads on the worm. A comparable spur gear set with a ratio of 40:1 would require at least two stages of gearing. Worm gears can achieve ratios of more than 300:1.

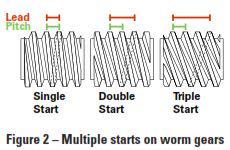

Worms can be made with multiple threads/starts as shown in Figure 2. The pitch of the thread remains constant while the lead of the thread increases. In these examples, the ratios relate to 40:1, 20:1, and 13.333:1 respectively.

Worm gear sets can be self-locking: the worm can drive the gear, but due to the inherent friction the gear cannot turn (back-drive) the worm. Typically only in ratios above 30:1. This self-locking action is reduced with wear, and should never be used as the primary braking mechanism of the application.

Worm gear sets can be self-locking: the worm can drive the gear, but due to the inherent friction the gear cannot turn (back-drive) the worm. Typically only in ratios above 30:1. This self-locking action is reduced with wear, and should never be used as the primary braking mechanism of the application.

The worm gear is usually bronze and the worm is steel, or hardened steel. The bronze component is designed to wear out before the worm because it is easier to replace.

Lubrication

Proper lubrication is particularly important with a worm gear set. While turning, the worm pushes against the load imposed on the worm gear. This results in sliding friction as compared to spur gearing that creates mostly rolling friction. The best way to minimize friction and metal-to-metal wear between the worm and worm gear is to use a viscous, high temperature compound gear lubricant (ISO 400 to 1000) with additives. While they prolong life and enhance performance, no lubricant additive can indefinitely prevent or overcome sliding wear.

Enveloping Worm Gears

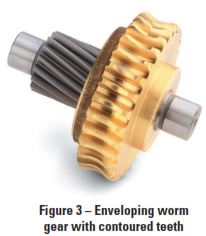

An enveloping worm gear set should be considered for applications that require very accurate positioning, high efficiency, and minimal backlash. In the enveloping worm gear assembly, the contour of the gear teeth, worm threads, or both are modified to increase its surface contact. Enveloping worm gear sets are less common and more expensive to manufacture.

An enveloping worm gear set should be considered for applications that require very accurate positioning, high efficiency, and minimal backlash. In the enveloping worm gear assembly, the contour of the gear teeth, worm threads, or both are modified to increase its surface contact. Enveloping worm gear sets are less common and more expensive to manufacture.

To download this article as a PDF, click here.

Copyright Bodine Electric Company © 04/2016. All rights reserved.